How to choose Nesting cutters? Discover the best tools for Nesting operations for each material, and find out why Wirutex hi-tech tools cutters are the right choice.

When it comes to mechanical techniques for processing wood and wood composites (and - as we shall see - other materials too), undoubtedly one of the most important yet delicate of these is Nesting.

The term Nesting is derived from “nest”, and indicates a nested structure created with the assistance of CAM software. This is used as the basis which enables optimised sizing of a panel on a CNC machining centre using specific tools, including Nesting cutters.

Nesting allows for productivity and efficiency increases, while maintaining high quality standards and rapid delivery times. Of the various operations that can be carried out, the most common are Nesting of furniture doors and parts, engraving on solid wood, panels and doors.

In this article, we will take a look at everything you need to know about Nesting cutters, and find out why the solutions offered by Wirutex hi-tech tools are the ideal choice for any application.

- Cutters for Nesting applications: how to choose the right one

- What is a Nesting operation?

- What are the best cutters for Nesting operations?

- Why choose Wirutex Router bits for Nesting

Cutters for Nesting applications: how to choose the right one

Knowing how to choose the right Nesting cutters - something that also depends on the material to be machined - is essential in order to avoid the risk of damaging the panel or failing to complete the machining operation.

Accordingly, the first criterion for choosing a cutter is the type of material to be machined: whether this is wood or composite.

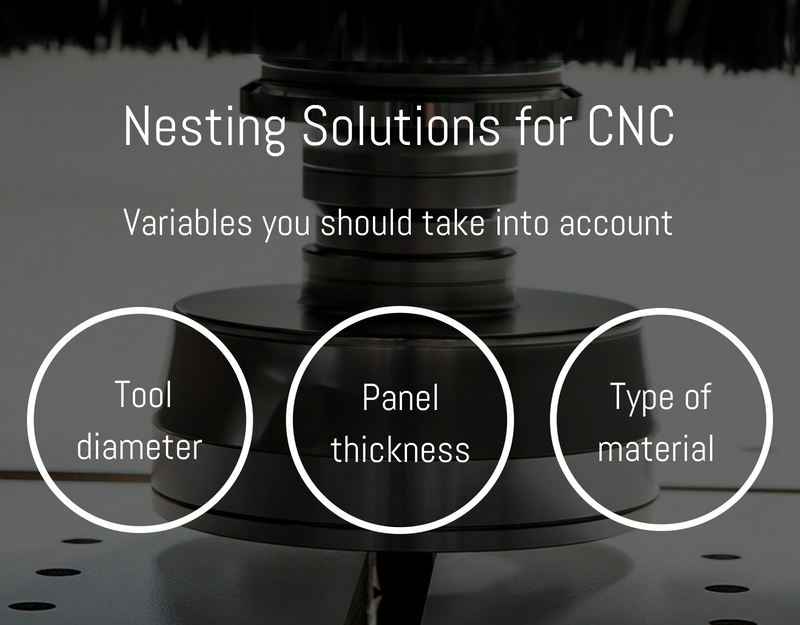

More specifically, one must take the thickness of the panel (H) into consideration, as well as the type of machining operation to be carried out. Finally, when it comes to CNC cutters, to make the right choice, it is essential to know:

- the cutter diameter (D);

- the cutting height (dependent on panel thickness);

- the type of chuck (thermogrip or hydrogrip).

Now that we have explored how to choose a cutter, let's take a look at how Nesting works.

What is a Nesting operation?

Nesting technology was created about forty years ago, with the appearance of the first computers available to large companies. From that moment, they have become more and more sophisticated and this process has seen unstoppable development and progress.

This particular machining operation is used in cutting flat panels – of materials such as wood, cardboard or sheet metal – is a production organisation technique aimed at reducing raw material wastage to a minimum.

Over the years, this optimisation process has increased thanks to the appearance of specific 3D CAD CAM software that organises your own Nesting projects by reducing the consumption of materials and processing times.

Nesting software is ideal for companies that need to produce complex, always different parts: thanks to these programmes, it is possible to plan the cut by defining, upstream, the parameters that are absolutely essential.

Also, the most modern automatic Nesting software today optimises productivity by trying to suggest the same cutting patterns that have already been designed and stored in a kind of virtual library that can be accessed at any time.

The benefits of the Nesting process

As seen, Nesting is an automatic optimisation procedure for cutting in order to reduce spaces and waste on the panel.

In brief, this process allows more parts to be positioned, which have already been designed using CAD modules, inside a single work surface and then marks routes that the Nesting tools must use, thus creating precise, pre-set cutting patterns based on the material undergoing machining.

Using a Nesting system for automated machining operations has the benefit of significantly reducing processing times whilst optimising production output, as a single passage in the machine allows all the pieces needed to be cut.

The other important advantage is minimal waste: for example, it is possible to cut and shape all the wood pieces that are needed to make a certain piece of furniture.

Finally, this machining operation has enormous potential, in that it enables a company to produce customised orders, thus providing any special request made by the client.

What are the best cutters for Nesting operations?

Evidently, the benefits discussed above are maximised when using the best cutters for Nesting machining operations, as these can guarantee the precision and durability of the cutting edge even when used in industrial processes.

At the beginning of this article, we mentioned that knowing how choose the right cutters for Nesting operations can guarantee that:

- best tool performance possible;

- good cut quality;

- optimal working conditions for the electrical chuck;

- optimised speed for production cost reduction.

But now, let’s take a look at the distinctive features of the most frequently used of these, which include polycrystalline diamond and tungsten carbide Nesting cutters.

In the Wirutex hi-tech tools product range, you can find both specific nesting burrs with tungsten carbide or heavy metal body, made with heat-resistant materials, and burrs for support panels.

Let’s get to know them in more detail.

Nesting cutters in polycrystalline diamond (PCD)

Wirutex's polycrystalline diamond (PCD) pantograph cutters for Nesting operations have an exceptionally long lifespan, and maintain superb cutting quality, even when machining abrasive materials such as MDF, plywood or laminates. For this reason, they are suitable for intensive applications.

More specifically, Nesting ECO is ideal for machining melamine and MDF panels, and can be used with any type of chuck, including Turbinex Dust Removal System..

Nesting HP, meanwhile, can also be used for machining operations on plywood and coated plywood materials on any type of chuck, including Aerotech®Hydro.

Finally, Nesting Revolution is the PCD Z2+2 pantograph cutter. Thanks to its versatility, it can be used to machine a range of different types of material. Compared to traditional Nesting Z3 cutters, it has a higher discharge capacity.

Lastly, the PCD planing cutter is designed for use on CNC machining centres for cleaning the support panel. This Nesting cutter is specifically for MDF panels, and is available in Z4 and Z6 versions.

Tungsten carbide (HW) Nesting cutters

Tungsten carbide (HW) cutters can be used on a wide variety of materials, providing a good balance between durability and purchase cost. These cutters are ideal for general machining operations and offer excellent performance across many different applications.

In the range of pantograph cutters for CNC machining centres by Wirutex hi-tech tools, you can find HW tungsten carbide cutters with interchangeable knives, specifically designed for planing the MDF support panel. The cutters for Nesting HW applications are available in both Z3 and Z4 versions.

The performance is outstanding. The planing cutter with interchangeable knives from Wirutex provides a variable maximum RPM of 12,000-18,000 and a feed speed of up to 15 metres per minute.

Why choose Wirutex Router bits for Nesting

In this article, we have seen how Nesting is a very efficient automated operation which can facilitate the production process, both with regard to quality and production output.

Wirutex hi-tech tools has created a dedicated Nesting Solutions programme, thanks to their decade of experience in the wood, plastics and aluminium machining tool technology sector.

Thanks to constant research in innovation and client-based tests, we have created a range of Nesting tools that allow maximum finish on various types of materials.

Our solutions include router bits with heavy metal bodies and the use of aspiration chucks/turbines Aerotech®.

Aerotech® is a new system that combines a high-precision chuck and suction turbine in one single product. A revolutionary product that captures dust and chips, channelling them to the machine’s suction system.

If you want more information, write to us or call us.