These high-precision tools have become essential in the woodworking industry, guaranteeing optimal results in the treatment of panels for a wide variety of solutions.

Finishing the edge of a wood panel professionally with a technologically advanced industrial machine allows to seal the end product from moisture penetration and to protect it from a mechanical point of view.

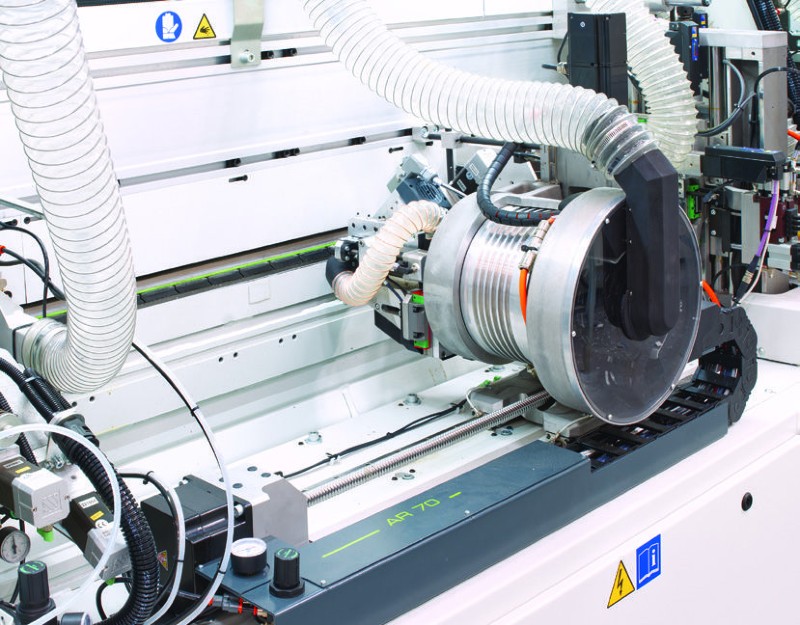

In this article, we would like to introduce you to the new Wirutex diamond multi-profile rounding cutter fitted as standard on the Biesse AR70 rounding unit, designed to offer highly efficient performance to companies that want to intensify their production capacities while maintaining high output standards.

In particular, we will talk about:

- Flexible and fast edgebanding of the wood with a single tool

- Perfect angles with a single tool for the edgebanding of wood and wood composites

Flexible and fast edgebanding of the wood with a single tool

The turmoil in the wood-panelling industry requires a change of pace in production processes, and the new wood edgebanding tools point in this direction.

In fact, the increased demand for customised products - with short delivery times and increasingly high quality standards - requires companies to use state-of-the-art, technologically advanced machines to keep their promises to their customers.

Quite a challenge to which the most forward-looking companies in the industry are responding with investments in machines and tools that allow to rapidly obtain maximum flexibility and production quality.

Among them, investments in wood edgebanding tools have certainly become essential for the modern furniture industry.

AR70, the new Biesse rounding unit for perfect wood edgebanding

A properly executed edgebanding of wood and wood composites is one that, upon close and careful inspection of the edges, presents a perfectly smooth surface, free of dents and chips. To the touch, the corners are smooth and without excess thickness on the perimeter edges.

How can the edge of a wood panel be finished to achieve such results? This was the challenge taken up by Biesse who, in partnership with Wirutex, designed the multi-profile rounding cutter for the AR70 rounding unit.

AR70 is the single rounding unit assembled as an option on Biesse's Stream A and Stream A Smart edgebanding machines. One of its advantages is that it can round corners at the bottom and top of the panel with a single motor and a single tool.

The technology of the AR70 rounding unit is able to satisfy customers who need maximum flexibility in the rounding section.

Most importantly, the AR70 rounding unit comes standard with the Wirutex diamond multi-profile rounding cutter, a single tool that comprises 4 different radii (3mm, 2mm, 1.5mm and 1mm) and a 25-degree bevel.

Thereby it is possible to machine the edge with five different options, all in one tool.

How does the edgebanding of wood and wood composites change with AR70?

Edgebanding machining operations of wood and wood composites with the AR70 rounding unit is definitely better than in the past. Not only for the greater efficiency in the machining process and the wider variety and customisation of profiles, but also for the ease with which the machine can be programmed.

The programming, which is completely software-based and allows the machining profile to be changed in the process, avoids interrupting the edgebanding process.

Furthermore, the servo control and multi-profile cutter combination has made machines equipped with the AR70 rounding unit one of the most popular with small and medium-sized manufacturers of quality furniture.

Thanks to the servo control and numerical control, the meeting point between the rounding unit and the panel can be defined and the pressure exerted can be adjusted automatically. In this way, any weak areas in the centre of the panel are not subject to deformation even when machining the most complex profiles.

From the operator's point of view, programming the machine simply means following the instructions on the control panel.

Perfect angles with a single tool for the edgebanding of wood and wood composites

Historically, users of mid-range edgebanding machines have had to decide on the thickness of the edge and select a radius to apply to it, usually 2 mm, 1.5 mm or 1 mm, sometimes 3 mm.

With a two-motor rounding unit, a compromise must inevitably be made: when changing from 2 mm to 1.5 mm you do not change the radius of the rounding cutter.

So, the result is to machine a 2 mm edge with a 1.5 mm radius or with a 1 mm radius on the corners.

This is not the case with the AR70 unit. In addition to enviable results in terms of wood edgebanding quality, machines equipped with an AR70 also allow, thanks to the Wirutex multi-profile rounding cutter, to automatically switch between 4 different radii and a 25-degree bevel angle or even create a customised profile.

From the software interface, you can also create customised profiles or import your own CAD file to use that profile in a few simple steps.

The operator enters information on the type of radius and where to apply it, the desired angle and whether it will be postformed. The results will be perfect corners and edges that are smooth to the touch.

If you would like more technical information on our wood edgebanding tools or our other products contact us and we will explain how you can improve your production process.

© Photo credit by Biesse